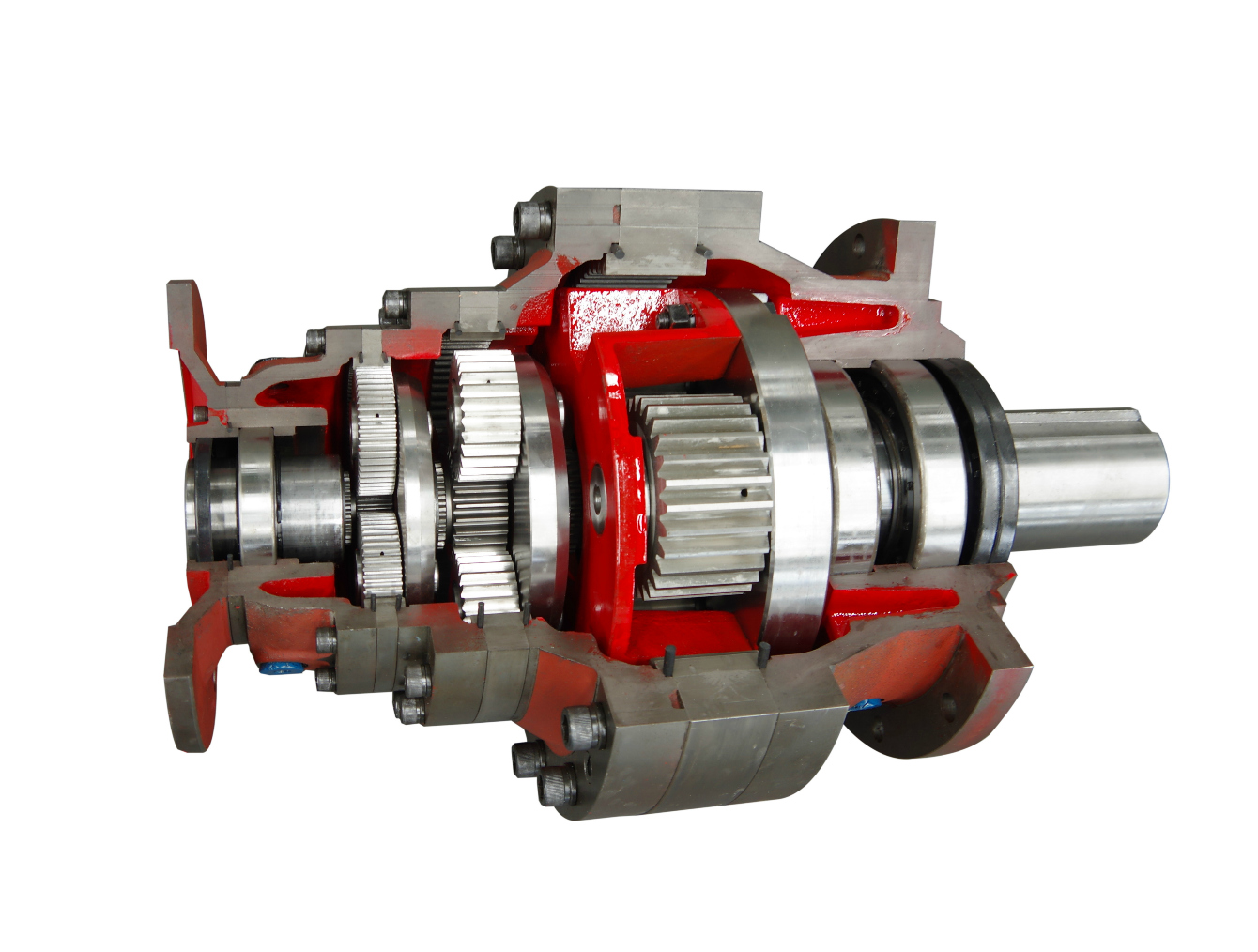

Series N3: 3 Stage Planetary Gearbox

| Output speed | 0.425‐445 r/min |

| Ratio range | 39.71-456.44 |

| Input power | 0.25‐55KW |

| Mounting position | all positions |

| Mounting dimensions | Standard /custom |

| Reduction ratio | i >3 |

| Permit torque range | ≤ 540000N. M |

Series N3: 3-Stage Planetary Gearbox

Our team’s 3-stage gearboxes for planetary applications (N3 series) are available in many low-speed shaft designs, including the cylindrical shaft fitted with a key or spline shaft hollow shaft that has a shrink disc or splined shaft.

Each three-stage planetary gearbox features an output bearing with a large capacity. This is why all of our 3-stage planetary gearboxes have high capacities in radial and axial dimensions. Additionally, they are resistant to the effects of overturning and increase the reliability of gearboxes and their efficiency.

To be a high-quality producer of planetary gearboxes; the tooth profiles of our planetary gearboxes 3 stages are precisely crafted for quiet noise operation.

If you require feet, flanges, or mount solutions we’ll make them to meet your requirements. Also, each part of the gearbox is subject to a rigorous quality control process prior to shipment.

Through the Planetary Gear Calculator, you can select from a range of outputs for speed and torque. The 3-stage planetary gearboxes we offer are designed to be modular and easily customizable.

Additionally, the 3-stage planetary gearbox comes with extremely stable and sturdy support. This guarantees high torsional stiffness for every gearbox.

The Key Features

The Key Features

- Modular design, combined according to the client’s requirements

- Heavy bearings, designed for heavy-duty use

- Long-lasting, hardened gearing with high reliability

- Low-speed shaft design

| Torque range | 1000 … 540000 Nm | Input | IEC Flange |

| Mechanical rating (n1 = 1500 min-1) | up to 200kW | Electric motor | |

| Gear ratios | 39.71-456.44 | Solid input shaft with or without fan cooling – inch or metric dims. | |

| Gear unit versions | Applicable AC motors | Integral motors and brake motors | |

| Right angle (with bevel gear set) | IEC-normalized motors and brake motors | ||

| Mounting type | Foot | Single and dual-speed motors | |

| Flange mounted | Main brake features | DC and AC supply | |

| Torque-arm | Faster brake reaction through an electronically controlled rectifier | ||

| Output shaft options | Solid shaft | Main motor options | Thermistors and thermostat sensors |

| Splined shaft | Independent forced cooling | ||

| Female splined shaft | Line driver and push-pull incremental encoder | ||

| Hollow shaft with shrink disc |

N series planetary gearbox torque sheet with models

| Gear unit size | 200 | 201 | 240 | 241 | 280 | 281 | 353/354 | 355 | 400 | 401 |

| Normal output torque T2N[Nm] |

1500 | 2000 | 3500 | 4000 | 4300 | 7300 | 13000 | 16000 | 20000 | 23000 |

| Gear unit size | 428 | 429 | 445 | 446 | 510 | 542 | 543 | 695 | 810 | 885 |

| Normal output torque T2N[Nm] |

26000 | 30000 | 32000 | 43000 | 63000 | 75000 | 100000 | 150000 | 300000 | 420000 |